Gage Choice

Since 1939, the instruments for measuring the pressure have been standardized by the American National Standards Institute (ANSI). Most gage manufacturers consistent in the face of the structure, the scale ranges and accuracy classes. Industry characteristics may be periodically reviewed and updated.

Gage accuracy is specified as the limit that the error should not exceed when an instrument is used in any combination nominal mode. It is expressed as a percentage of the total pressure (dial) range. Classification sensors ANSI has a significant impact on other stages gage design and specifications. For example, a test-gage with 0.25% accuracy will not be offered in the 2nd century the size of the face. The readability of a smaller set is not necessary accuracy of input required for this degree of accuracy. Most sensors with accuracy 0,5%, and it is better to have a set that at least 4.5 century Readability can be improved still further, increasing the size of the dial.

Precision exactly How many is enough? It is a question only the programmer can answer.

However, from gage point of view of a producer, increased accuracy represents the proportional increase of the construction cost gage. Tolerances each component should be more strict, as gage accuracy increases. The time required for technicians calibration of the meter correctly. A wide variety of high-precision instruments available and evaluation (1%), 2A (0,5%)and 3A (0.25%) are examples of tolerances.

With the advent of modern electronic devices and more sophisticated equipment, you can still retrieve dreamed of accuracy automatically equipment used in the field. Average each gage selection of measured liquid, should be evaluated for potential corrosion-ness to the Bourdon tube gauge. There is no ideal material for the Bourdon tube. None of the material adapts to all applications. Bourdon tube materials are selected for their resilience, stability, ability to resist to "set" and corrosion resistance for liquid media.

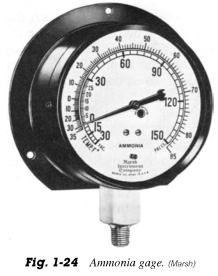

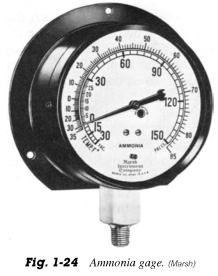

Ammonia refrigerants usually used in refrigeration. All steel internal construction is required. Ammonia thickness gauges have the appropriate temperature scales. Restriction screw protects the unit from the sudden blow, blow, or pulsating pressure. Heavy-duty movement stainless steel and alloy steel, Monel prevents corrosion and ensures extra-long life. The inner arc of the dial shows the pressure. Another arc shows the proper temperature. Cm. Fig. 1-24.

.. ..

|

..

..