Absorption Refrigeration Systems. Steam ejector recompression ARS

Ejector recompression absorption cycle, which was recently developed Ames and Wu (2000), similar to the conventional single-effect of lithium bromide absorption cycle. The difference between them is that there is a steam ejector in this novel cycle of increasing the concentration process. Due to the use of steam ejector, performance and operational characteristics of the novel in the series differs from a normal cycle.

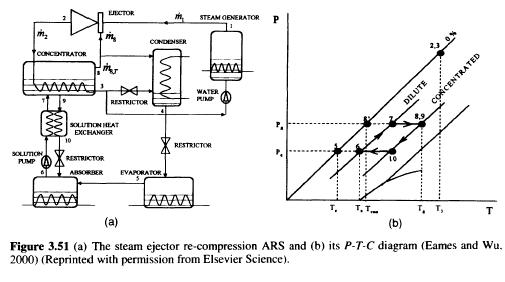

Steam ejector recompression absorption cycle is shown schematically in Fig. 3.51a. In this figure, the expansion of high-pressure steam causes of the low pressure at the outlet from the initial steam ejector nozzle, so a couple in paragraph 8 in the hub defined the primary thread. Two threads are mixed in the steam ejector and are condensed in the exchanger concentrator. Condensation heat is used for heating of the solution in the hub. Obviously, the heat accumulated pair recovered by steam ejector in this process. Water at the point 3 is divided into two streams; one flows into the steam generator and other acts in the condenser.

In the stable functioning of the mass flow rate of the first stream is equal to the main flow, mass flow rate of the second stream is equal to the accumulated pair. The rest of the cycle is similar to the conventional single-effect of lithium bromide absorption cycle. Fig. 3.51b shows novel in the series P-T-C-scheme. As shown in Fig. 3.51b, cycle 6-7-9-10-6 takes water absorber (10-6) and releases it as vapor at concentrating factory (7-9). The usual absorption cycle, vapor condenses on the 8′ and condensation heat is rejected to the atmosphere. In the novel-cycle, this pair is in the process of compression through the ejector in point 2. Because the temperature of the steam is higher than the temperature of the solution in the hub, this pair is used for heating of the solution by condensation to point 3. Therefore the heat otherwise wasted restored and energy efficiency is improved.

Ames and Wu (2000) investigated the efficiency of power consumption and performance characteristics of the novel in the series and theoretical results showed that the COP novel cycle better than conventional single-effect absorption cycle. Characteristics of the cycle performance show his promise in the use of high-temperature heat source at a low cost. Recently, Kang et al. (2000) conducted a study to suggest and evaluate advanced absorption cycles for COP improvement and temperature Elevator increase in applications. The characteristics of each cycle is estimated from the point of view of a perfect cycle of the COP and its applications. Additional cycles to the COP improvement classified according to their heat recovery method condensation heat recovery, heat absorption and condensation/heat absorption. In the H2O-LiBr systems, many of the effects and the number of stages can be improved by adding a third or a fourth component to solve pairs. Performance NH3-H2O system can be improved by heat recovery due to their thermal characteristics, such as temperature gliding. NH3, H2O cycles can be combined with adsorption cycles and power cycles for waste heat utilization, productivity, panel heating and low temperatures. H2O-LiBr cycle preferably with a high COP in terms of evaporation temperature during 0VC, while NH3, H2O cycle is best from the point of view of low temperatures. In this study suggests that the cycle performance would be significantly improved by combining advanced H2O-LiBr and NH3-H2O cycles.

..

|