Why Control Condenser Capacity?

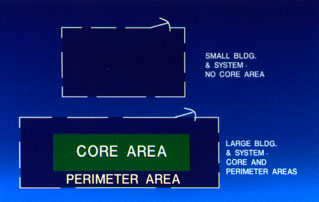

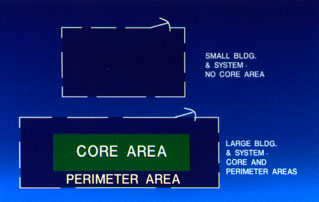

As in the case of compressors, condensers, installed in small capacity systems rarely use sophisticated techniques for performance management. Systems up to 5 tons of cooling capacity, and especially to 3 tons and less, as a rule, function well without a separate tank management systems for the condenser. The larger the system, the more likely that there will be a need for mechanical cooling at low temperatures. This is because larger buildings, with large systems, the key areas that have a load of cooling (heating) whenever they are busy and lit it, regardless of the season. The operation and then the cooling system at low temperatures presents some special needs, for example, the head pressure control. And here's why.

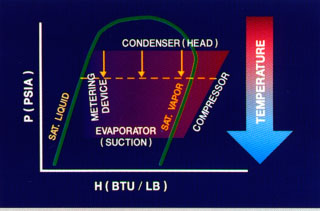

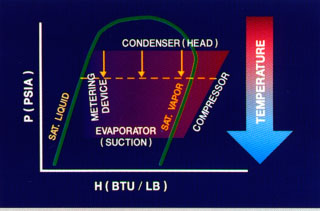

As the temperature drops, the outdoor air pressure of the air cooling system. Similarly, the decrease of temperature of external air or moisture reduces wet bulb temperature of the air flowing through cooling towers or evaporative condenser.

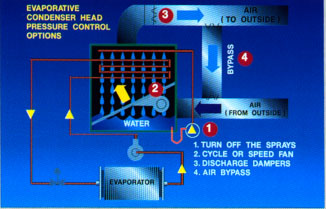

Below wet bulb temperature produces lower the temperature of the condenser water, which, in turn, reduces the refrigerant (head) pressure and the saturation temperature at the condenser. This reduction is of benefit to the system energy efficiency, as produce compressors are more efficient when the pressure changes they produce decreases. However, there is a limit to how low head pressure may drop down to dozatora the liquid stops functioning properly. Head control system power capacitor control systems designed to maintain the system in a head pressure on the minimum level.

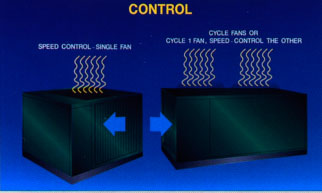

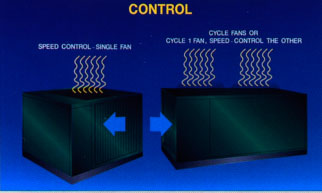

Air-cooled condensers achievements head pressure control, most often, Cycling and off as required. Single-fan models sometimes the use of a variable speed fan motor that controls the speed down, as indicated sensing saturated condensing temperature. The lower the temperature of condensation, the fan runs slower. The combination of Cycling all but one fan and regulation of recent fan can produce a smooth refrigerant control when the outdoor temperature is below -20F. Commercial refrigeration and industrial applications sometimes control head pressure, air cooled condensers, valves in the refrigeration system pipelines instead of controlling the fan(s). This causes some of the refrigerant, which will be held in the condenser, floods a portion of it. Floodback management, as it is called, has the same effect, reducing the size of the condenser coil, because only unflooded part can be condensed refrigerant.

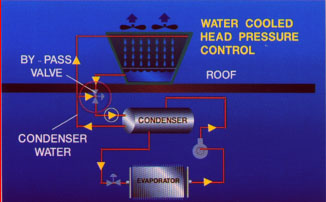

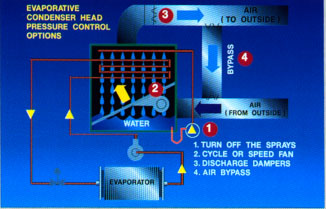

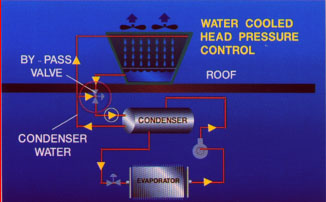

Water cooled condenser systems most often used water valve, which skips the tower and a mixture of water towers of the condenser water. This allows condenser water will be maintained at the desired high temperature, which, in turn, raises his head pressure to the required level. Bypass valve is usually controlled water temperature at the condenser inlet. Cycling fans or movable tower slots can also be used.

Automatic problem in the condenser, are likely to result in the final compressor failure. If the technician replaces the compressor without revealing and elimination of the main cause of the compressor will bring. Repeat compressor failures are serious problems in the field of air-conditioning. They lead to unhappy customers, and also the excessive cost of labor and parts dealers and manufacturers. One of the things that you should strive to exit the GTAC the program of deep understanding of the causes and symptoms of compressor failure and how each component can contribute to such failures. Ways capacitors can contribute to a compressor failure here. Also there is the Troubleshooting guide at the end of this module, which goes into detail about the capacitor problems, their symptoms, causes,...

|