|

|

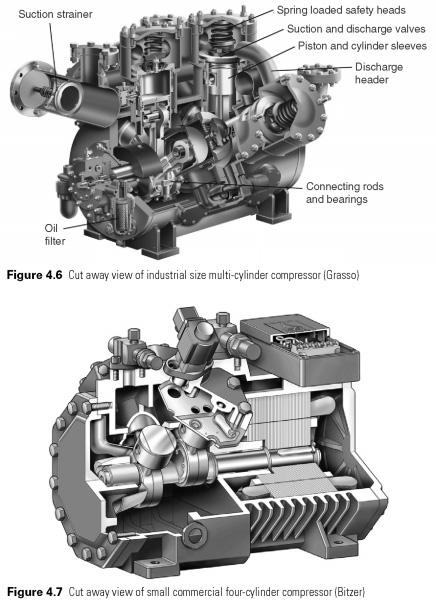

Multi-cylinder compressors

To achieve greater power, compressors were made during the first years of development, have cylinder bores up to 375 mm and operates at speeds of up to 400 rpm Result of the components have been heavy and bulky. To take advantage of larger-scale methods of production and of exchange-the ability parts, modern compressors multi-cylinder with holes the size of not more than 175 mm at high speeds of rotation of a shaft. Machines of four, six and eight cylinders are common. Fig. 4.6 shows a large reciprocating engines are constructed of welded steel Carter, the largest of this type can accommodate up to 1000 kW.

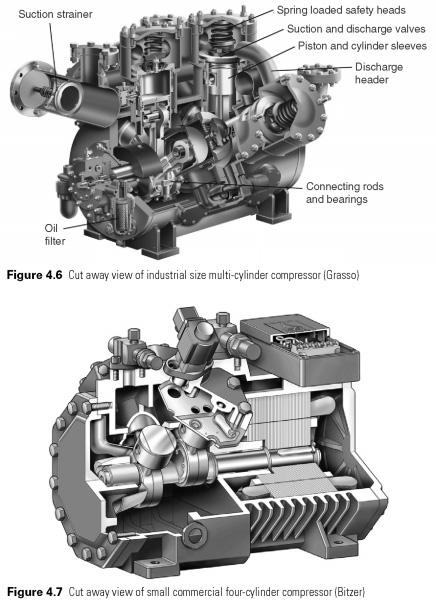

Cylinders are, as a rule, banks with two, three or four cores on one roll of the crankshaft to give a short, hard machine. This construction gives a large number of the common parts - pistons, connecting rods, bulk liners and valves - through a range of compressors, and such parts can be replaced in case of wear or damage, not removing the compressor body since its installation. Compressors for small systems, it will be easier, consisting of two, three or four cylinder (see Fig. 4.7).

....

|